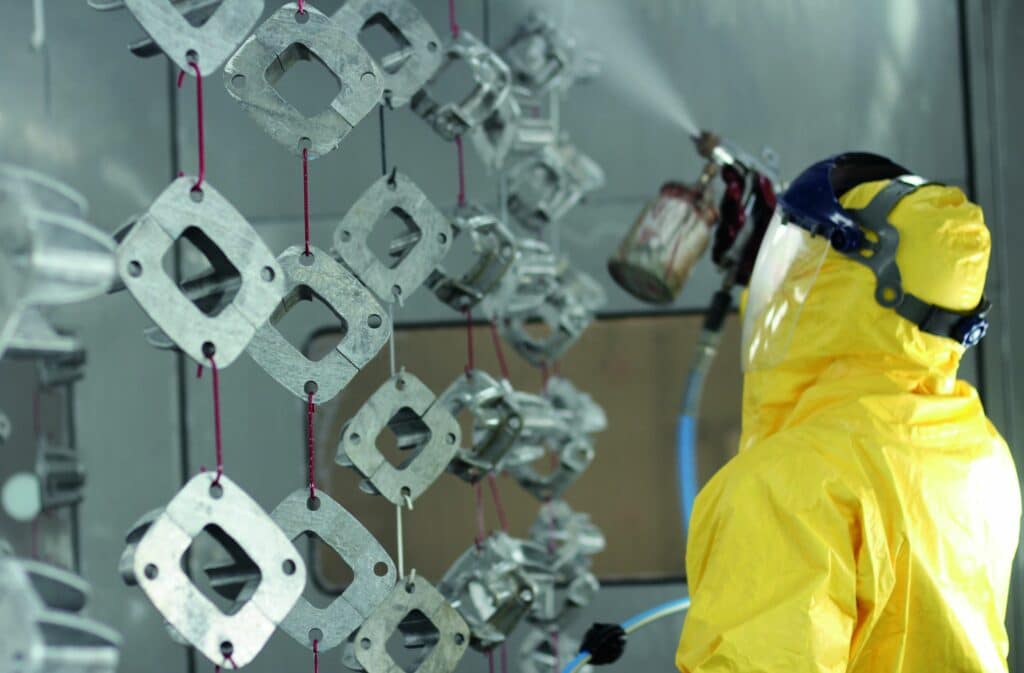

The very complex profession of surface treatment requires perfect knowledge of the customer’s needs.

Indeed, the final destination of the part, the material, the final use, are preponderant elements for the choice of the treatment, the products and the equipment to be used.

The OTS Group and its subsidiary Abratech have chosen to invest heavily in the preparation of materials and the application of powder paint and liquid paint in order to meet your needs.

From simple aesthetic treatment to extreme anti-corrosion, our teams are committed to responding in the most appropriate way, with economic solutions linked to the recent equipment of our manufacturing sites.

For an impeccable end result, we offer you various surface preparation treatments to eliminate scale and grease, eliminate rust and oxidation.

We can also offer you the removal of old paints, coatings and concretions in order to create a gripping surface necessary for metallization, powder or liquid paint.

We offer you 2 free-jet shot blasting booths with INOX shot blasting:

Cabin with dry filtration booster:

One of our latest investments concerns the ANTICORROSION treatment activity: the metallization by fusion spraying of ZINC or ZINC-ALU on previously stripped parts.

This coating acts as a cathodic barrier against any corrosive agent for a long time with a reduced maintenance cost.

Excellent grip for a paint system. No deformation or modification of the metal structure is to be feared.

Cabin capacity: L.10,000 x l. 4500 x h. 3500

2 distinct means of production

The powder coating is made from epoxy powder, thermosetting epoxy polyester which is polymerized, after application in an oven. Many plain and metallic colors exist as well as grained, sandblasted, hammered textures, etc.

Automated chain with overhead conveyor

4-storey spray treatment tunnel:

phosphate degreaser,

city water rinsing,

non-chromic passivation,

rinsing with demineralised water

Drying oven

CN powder coating booth

Polymerization oven

Full size cabin

Cooking oven L.8200 x l.3080 x h.3360

Liquid range applied by spray Mono and bi-component Epoxy / Polyurethane / Alkyd.

Complete offer including Special Coatings:

Double module liquid paint booth dimensions: L.12,040 x l. 3920 x h. 336